Use-case – Diagnosing an automotive engine

This use-case is taken from the conference paper

E. Frisk, M. Krysander, and D. Jung “A Toolbox for Analysis and Design of Model Based Diagnosis Systems for Large Scale Models”, IFAC World Congress, Toulouse, France, 2017.

where the interested reader can find more complete explanations and a full set of references for explainations to used concepts and methods.

This use-case is presented using the Matlab toolbox, but all commands in the use-case have direct counterparts in the Python toolbox.

Outline

- Introduction

- Modelling

- Diagnosability Analysis

- Residual Generator Analysis and Design

- Evaluation on Test Cell Measurements

Introduction

The air-path of an automotive gasoline engine is important for

understanding how much fuel to inject, how to keep combustion emissions low,

protect exhaust catalysts, and optimize efficiency. This system is not only

industrially relevant, it is also an interesting system for academic basic

research due to its complexity, its highly interconnected subsystems due to turbocharging, and

challenging to model accurately. The model used here is based on a control oriented model of the air-path

consisting of pressure dynamics that describe flows and thermodynamic relations to

describe temperatures and heat flows. The model has 94 equations and

14 states. The model is highly non-linear, has

external, mapped, functions implemented as lookup-tables, and hybrid

mode-switching statements (if-statements).

The air-path of an automotive gasoline engine is important for

understanding how much fuel to inject, how to keep combustion emissions low,

protect exhaust catalysts, and optimize efficiency. This system is not only

industrially relevant, it is also an interesting system for academic basic

research due to its complexity, its highly interconnected subsystems due to turbocharging, and

challenging to model accurately. The model used here is based on a control oriented model of the air-path

consisting of pressure dynamics that describe flows and thermodynamic relations to

describe temperatures and heat flows. The model has 94 equations and

14 states. The model is highly non-linear, has

external, mapped, functions implemented as lookup-tables, and hybrid

mode-switching statements (if-statements).

The measurements/control outputs used, in total 10, are: pressure sensors (throttle, intake manifold, ambient), temperature sensors (throttle, ambient), intake air mass flow, engine speed, throttle position, waste-gate position, and commanded amount of injected fuel. The considered faults, in total 11, are: Clogging of the air filter, leakages (before compressor, after throttle, before intercooler), stuck intake valve, increased turbine friction, sensors (throttle position, air mass flow, intake manifold pressure, pressure before throttle, temperature before throttle)

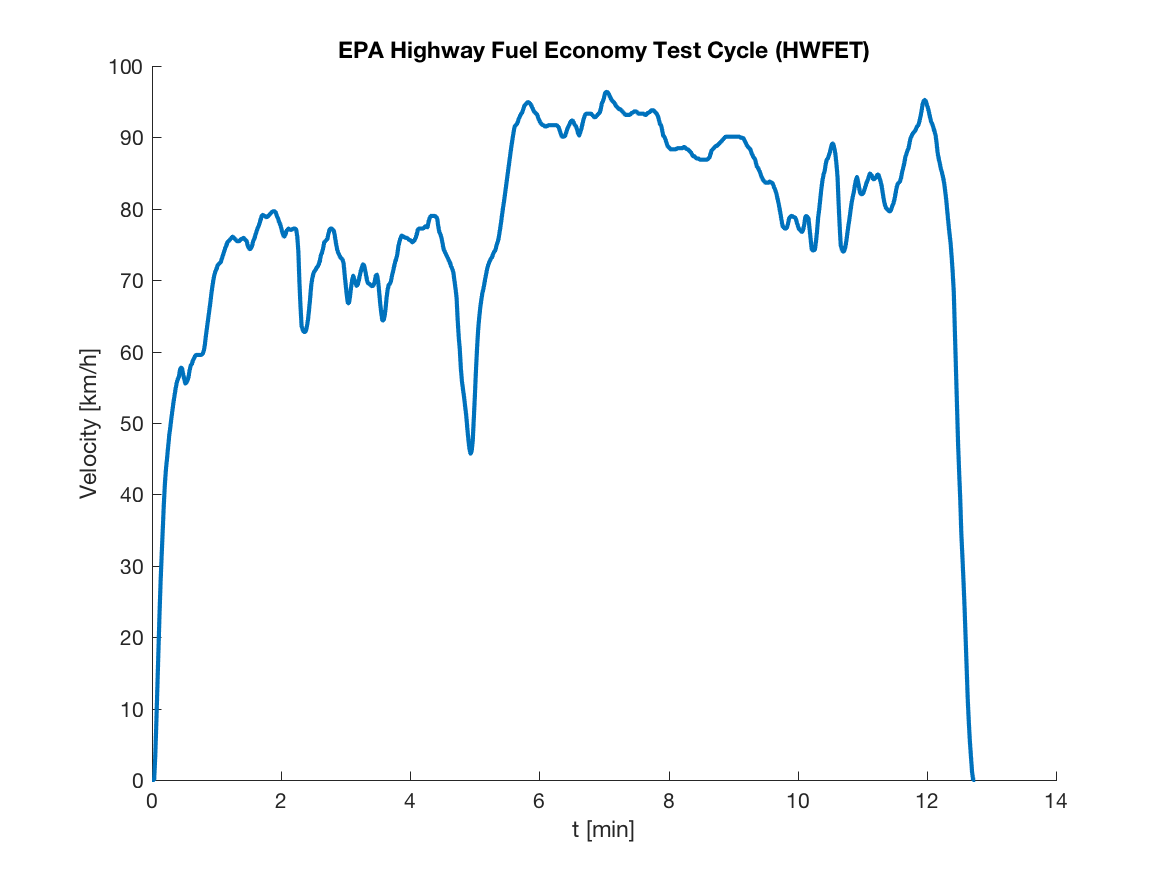

Measurement data is obtained in an engine test cell at Vehicular Systems.

The engine, a standard production engine, is equipped with a development control system

and subjected to load conditions corresponding to a car driving the EPA Highway Fuel Economy Test Cycle.

Engine operation is thus transient, although not violently so, and correct handling

of dynamic engine behavior in the diagnosis system is essential. The objective is then to,

during normal operation, detect and isolate the faults with a given false alarm probability and

optimize detection performance.

Measurement data is obtained in an engine test cell at Vehicular Systems.

The engine, a standard production engine, is equipped with a development control system

and subjected to load conditions corresponding to a car driving the EPA Highway Fuel Economy Test Cycle.

Engine operation is thus transient, although not violently so, and correct handling

of dynamic engine behavior in the diagnosis system is essential. The objective is then to,

during normal operation, detect and isolate the faults with a given false alarm probability and

optimize detection performance.

Modelling

The model is a differential-algebraic (DAE) model, based on the model developed in Eriksson, L. (2007). Modeling and control of turbocharged SI and DI engines. Oil & Gas Science and Technology - Rev. IFP, 62(4), 523–538.

The model-object is created by a statement

m = DiagnosisModel(modelDef)where the struct modelDef is a model definition containing the fields

modelDef.x- cell array of names of unknown variablesmodelDef.f- cell array of names of fault variablesmodelDef.z- cell array of names of known variablesmodelDef.parameters- cell array of parameter namesmodelDef.rels- cell array with model equations

In addition, the model relations/equations are written directly as

symbolic expressions. For example, a restriction model using an

external function W_af_fun, a control volume with a mass

state m_im and a temperature state T_im, and a

measurement equation for the air mass flow W_af can be written

as

%% Declare model equations

modelDef.rels = {

...

% Air filter restriction:

W_af == W_af_fun(p_amb,p_af,plin_af,

H_af,T_amb)+fp_af

% Control volume intake manifold:

p_im == m_im*R_air*T_im/V_im

dmdt_im == (W_th - W_ac) + fw_th

dTdt_im == (W_th*cv_air*(T_imcr-T_im)+R_air*

(T_imcr*W_th-T_im*W_ac))/(m_im*cv_air)

% Measurement signals:

y_W_af == W_af + fyw_af % Air mass flow

...

}The toolbox supports only structural models, but here models with symbolic

model equations is used since the objective of the use case is to go

from model to generating code for residual generators and then expressions

for the model equations are needed. When the modelDef structure has been defined and

the model object has been created it is time to explore the

model. Basic model information is obtained using the Lint class method

>> model.Lint()

Model: Engine model

Type: Symbolic, dynamic

Variables and equations

90 unknown variables

10 known variables

11 fault variables

94 equations, including 14 differential

constraints

Degree of redundancy: 4

Degree of redundancy of MTES set: 1

Model validation finished with 0 errors and

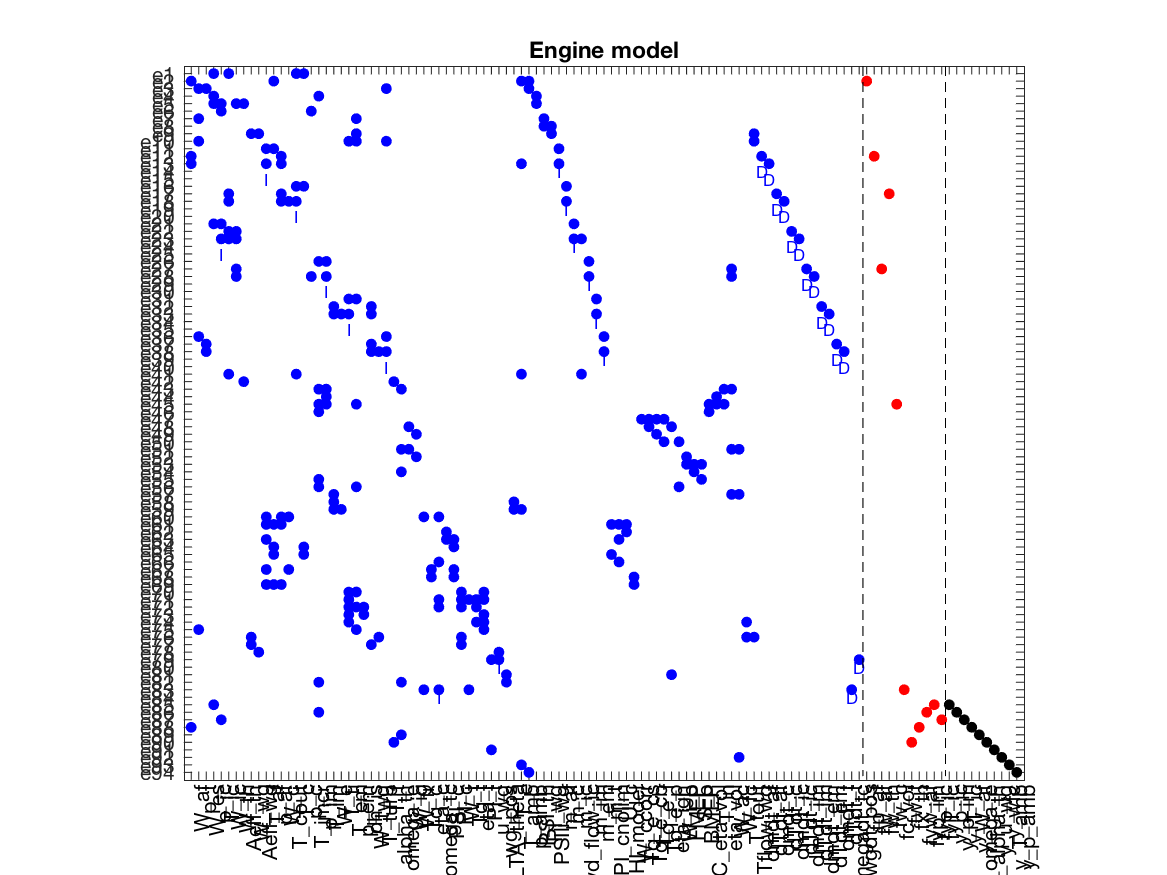

0 warnings. The model structure, i.e., which variables that appear in which constraints, are

extensively used by the methods implemented in the toolbox. This model structure

is automatically inferred from the model equations and the

The model structure, i.e., which variables that appear in which constraints, are

extensively used by the methods implemented in the toolbox. This model structure

is automatically inferred from the model equations and the PlotModel class method can

be used to visualize the model structure. It shows the equations on the vertical axis

and the variables on the horizontal axis. A dot represent that a

variable appears in the corresponding equation. Blue, red, and black

dots represent unknown, fault, and known variables respectively.

>> model.PlotModel()Diagnosability Analysis

Now, with a defined model there are many diagnosis analyses that can be performed on the model structure only. For example, it is possible to find out if the model contains enough redundancy to detect and isolate faults, i.e., answer diagnosability questions like

“Can I detect this fault?” or “Can I isolate this fault from that fault?” or “What isolation performance is possible using only direct application of state-observers?”

Such non-trivial questions can be answered using structural techniques giving best-case results.

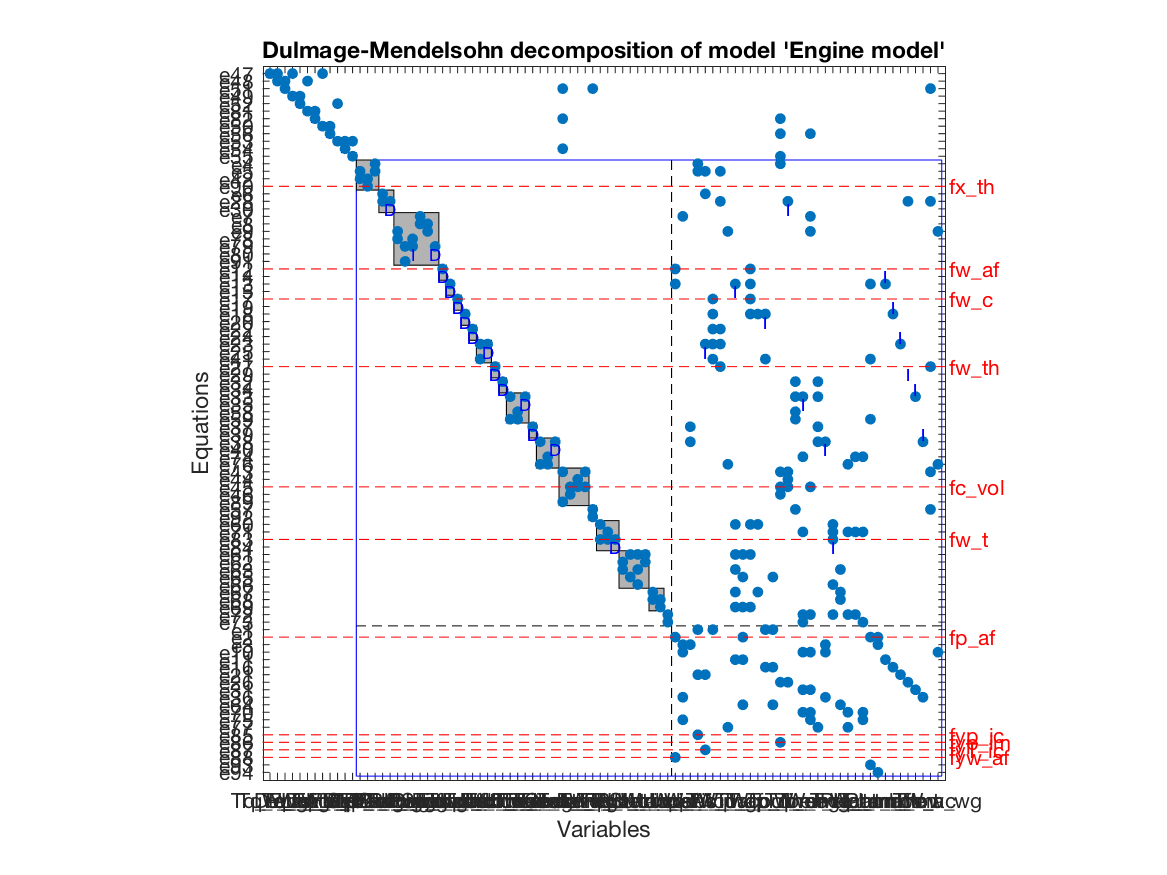

A canonical decomposition

A key tool in structural analysis for fault diagnosis is the

Dulmage-Mendelsohn decomposition.

To plot the decomposition, extended with fault variables and equivalence classes

as described in (Krysander and Frisk, 2008),

is computed using the PlotDM class method

model.PlotDM('eqclass', true, 'fault', true)which results in the plot

It is a Dulmage-Mendelsohn decomposition with an additional canonical decomposition of the overdetermined part. The overdetermined part is marked with a blue rectangle and faults entering in equations contained in the overdetermined part are structurally detectable. The set of equations in the overdetermined part is partitioned into equivalence classes, indicated by gray shaded rectangles in the figure, with the property that all faults appearing in the same equivalence class is not structurally isolable from each other.

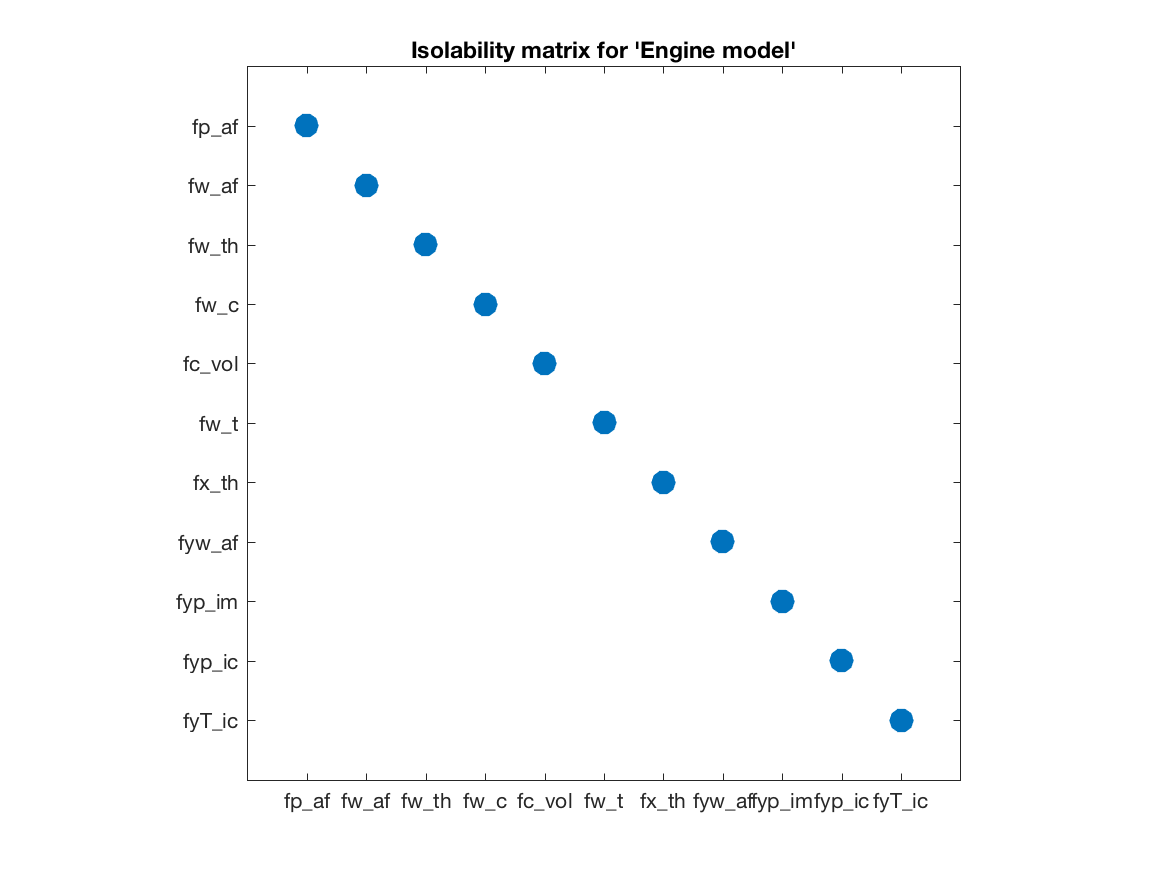

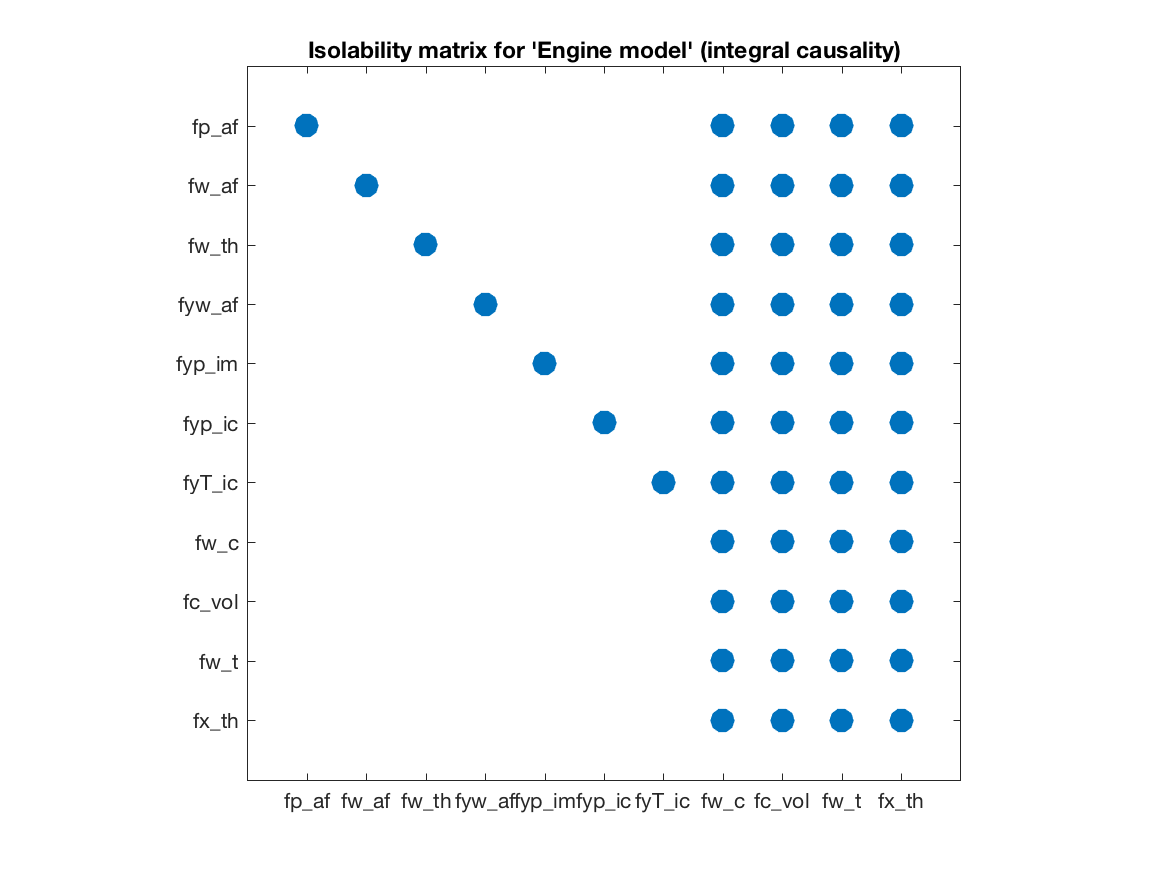

Fault isolability Matrices

Although the canonical form is informative, it contains

a lot of details. Another form of illustrating single fault

isolability performance is the isolability matrix computed using

the class method IsolabilityAnalysis as

model.IsolabilityAnalysis() A dot in position (i,j) indicates fault j will be a diagnosis if

fault i is the present fault. Thus a diagonal matrix represents full

single fault isolability, i.e., all single faults are uniquely

structurally isolable in the engine model.

A dot in position (i,j) indicates fault j will be a diagnosis if

fault i is the present fault. Thus a diagonal matrix represents full

single fault isolability, i.e., all single faults are uniquely

structurally isolable in the engine model.

Low structural index is an interesting class of models since, for example, for low-index models established techniques like state-observers and Extended Kalman Filters can be directly applied while this is not true for high-index models. The isolability of faults when only using low-index approaches can be computed by

model.IsolabilityAnalysis('causality','int') The isolability matrix shows how the fault isolability performance

degrades, which is expected, if the residual generation techniques are

limited to pure integration based methods. These isolability matrices gives a

direct way to early evaluate possible isolation performance of the model

and with the given measurements. Of course, these are structural results meaning

that even if the isolability matrix indicate that all faults are uniquely

isolable, it is not certain that this is realizable in the real application with

a required detection and false-alarm probabilities. But is gives an important

first indication on what is possible.

The isolability matrix shows how the fault isolability performance

degrades, which is expected, if the residual generation techniques are

limited to pure integration based methods. These isolability matrices gives a

direct way to early evaluate possible isolation performance of the model

and with the given measurements. Of course, these are structural results meaning

that even if the isolability matrix indicate that all faults are uniquely

isolable, it is not certain that this is realizable in the real application with

a required detection and false-alarm probabilities. But is gives an important

first indication on what is possible.

Residual Generator Analysis and Design

One successful approach to residual generation is to find testable

sub-models and then, based on such sub-models, design residual

generators. The first step is then to make a complete search for

testable sub-models, here Minimally Structurally Overdetermined (MSO)

set of equations. This step is based only on the

structure of the model and in the engine model there are 4496 MSO

sets. This means that, even with redundancy degree of only 4, there

are several thousand different sub-models that can be tested

independently. In the software, to compute the set of MSO sets use the

MSO class method as

msos = model.MSO();The output msos is a cell array of index vectors to equations in the model.

It is possible to compute the isolability of all MSO sets as

model.IsolabilityAnalysisArrs(msos)that is equal to the isolability matrix computed earlier.

Low-index and observability properties of sub-models

The toolbox supports sequential residual generator design and for models

with high differential-index such direct residual design is not always

appropriate since numerical differentiation of measurement

signals are needed. The structural differential-index can be

determined by efficient structural algorithms and the MSO sets with

low-index can be found using the IsLowIndex class method as

lowidx=cellfun(@(m) model.IsLowIndex(m), msos)For the engine model there are 206 low-index MSO sets out of the 4496. Performing the call

model.IsolabilityAnalysisArrs(msos(lowidx))will give the isolability properties of the low-index MSO sets previously computed; the isolability matrix with integral causality.

If a state-observer technique is to be used, observability of the

sub-models is of importance. Structural observability can easily be

checked, for all MSO sets, with the class method IsObservable as

obs=cellfun(@(m) model.IsObservable(m), msos)In the engine model, all MSO sets are structurally observable.

Sequential residual generation

There are many ways to design a residual generator based on a model

with redundancy. Sequential residual generation is one direct and

simple way, especially if the model is of low differential index. An

MSO set have exactly one more equation than the number of unknown

variables and this means that if one equation is used as the residual

equation, the remaining equations will form an exactly determined

system of equations. Then, the exactly determined set of equations is

solved for all unknown variables numerically on-line and insertion of

all computed variables in the residual equation then produces a

residual. For the engine model there were 4496 different MSO sets and

previous analysis gives that there exists 206 low-index

sub-models. From these 206 sub-models the toolbox can automatically

generate a large number, here 728, of candidate residual generators

with integral causality. Using the IsLowIndex class method, it

is concluded that MSO number 1650 with its 74:th equation as a

residual equation constitute a low-index problem. A matching, i.e.,

computational path for the exactly determined model is found using the

class method Matching and then the method SeqResGen

can be used to generate Matlab or C-code.

M = msos{1650}; % Set of equations

r = M(74); % Redundant equation

M0 = setdiff(M,r); % Exactly determined part

Gamma = model.Matching(M0); % Compute matching

model.SeqResGen(Gamma, r, 'ResGen_1650_74', 'language', 'C'); % Generate code

mex ResGen_1650_74.cc % CompileThis generates an object code that can be called directly from Matlab with measurement data and model parameters as inputs and the residual as output. Next step is to evaluate generated code for a set of such residuals on measurement data.

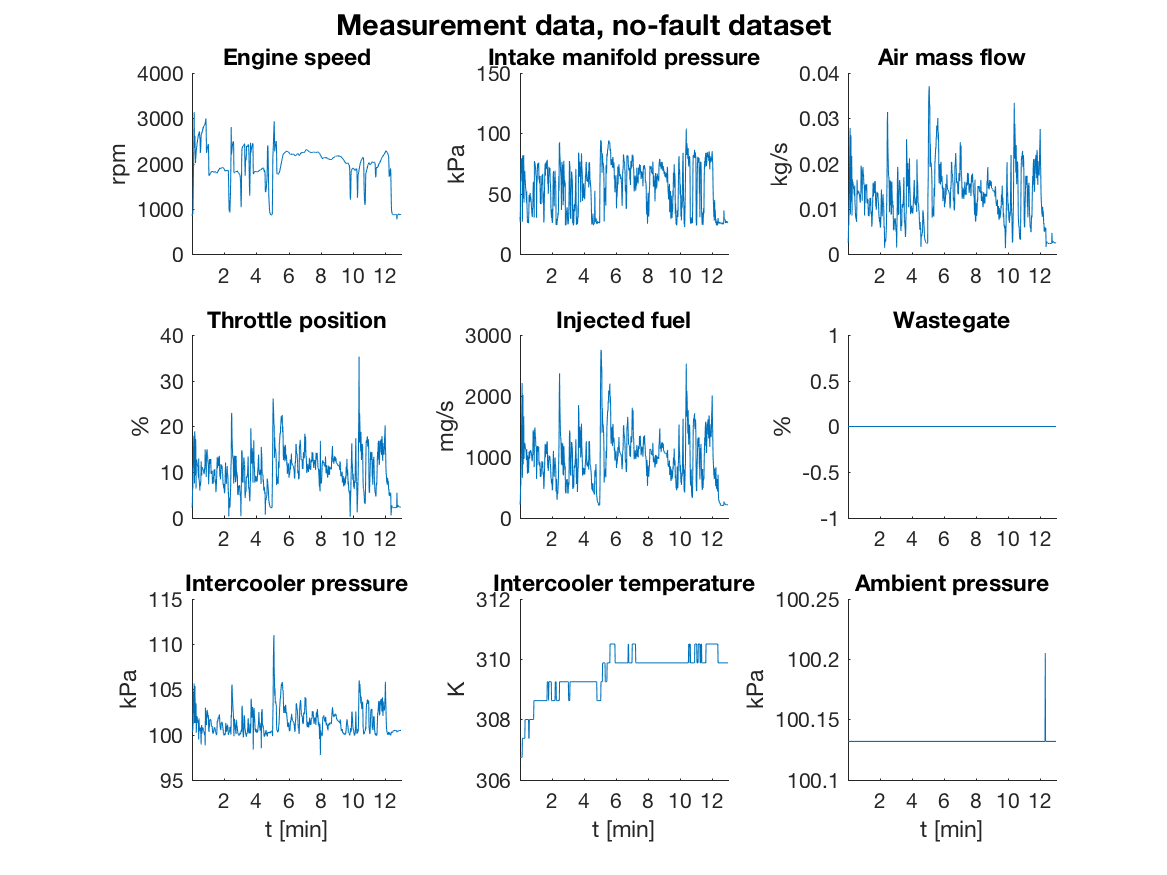

Evaluation on Test Cell Measurements

To illustrate performance on measurement data we consider only 4 of

the 11 faults; faults in the air-flow sensor fy_waf, the intake

manifold pressure sensor fyp_im, the intercooler pressure

sensor fyp_ic, and the intercooler temperature sensor

fyT_ic. Measurement data were collected for the fault free and

4 faulty cases, then in total 5 data sets, during a 12 minute long EPA highway

fuel economy test cycle. Sample measurements from the fault free case are

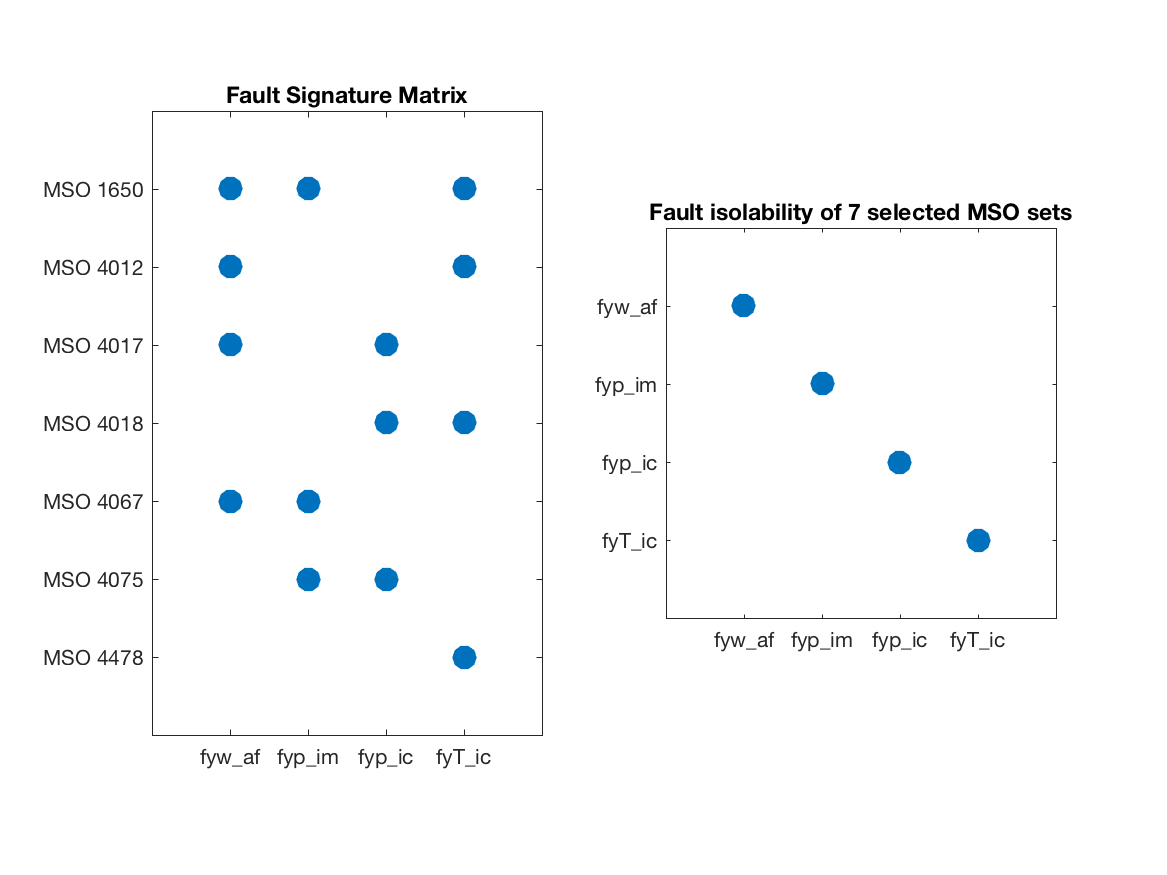

Out of the 728 residuals only a few is needed for isolating between

the 4 faults and using a data-driven test selection procedure not

described here, 7 residuals were in the end chosen for this

illustration. Using class methods FSM and

IsolabilityAnalysisArrs, the fault signature matrix and the

isolability matrix of the selected 7 residuals are

As can be seen, all single faults are structurally isolable.

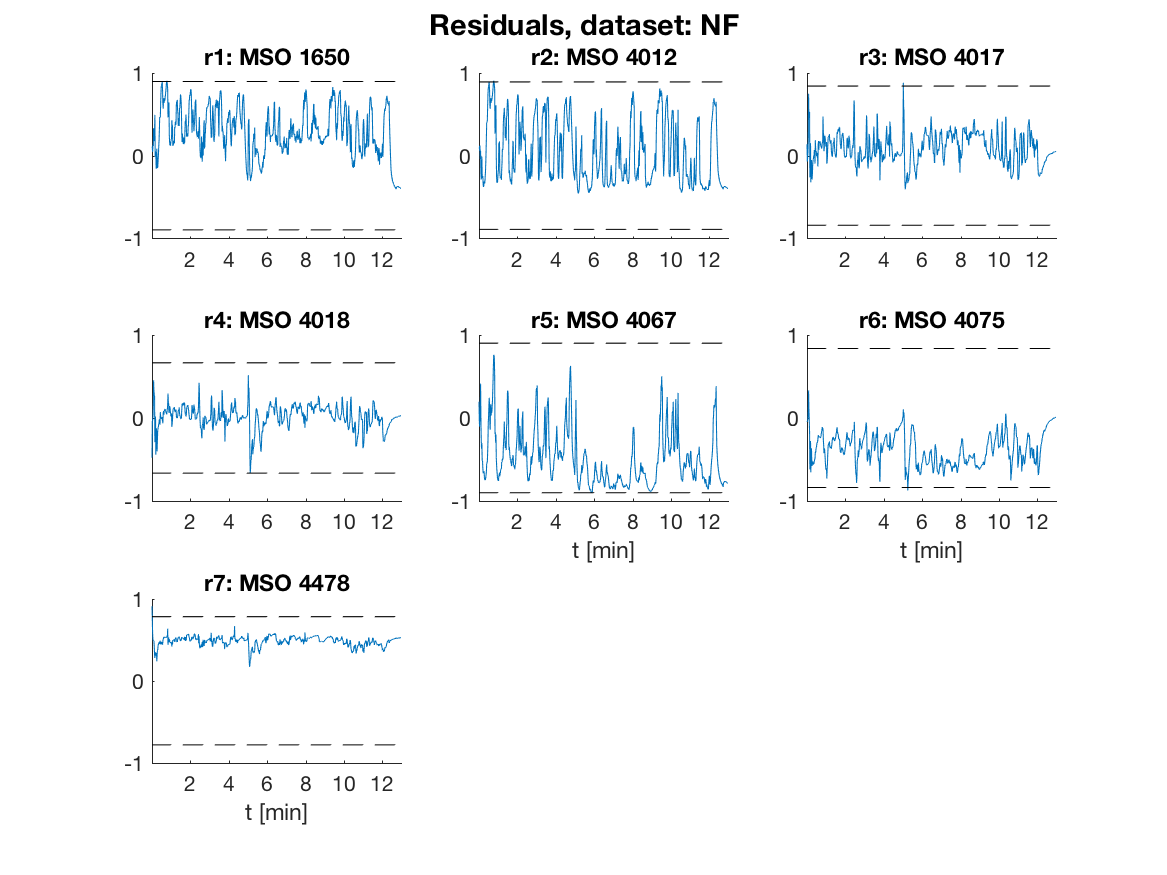

Running residual generators

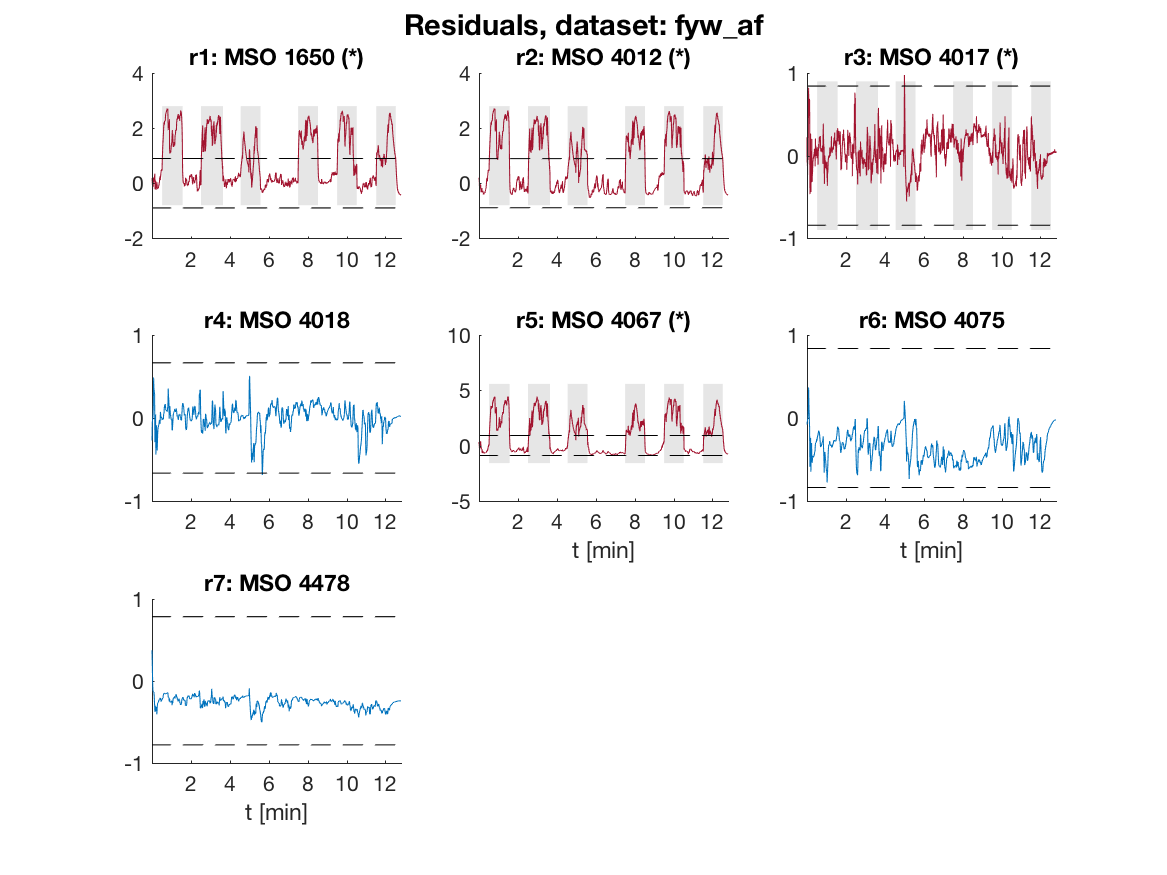

The generated code for the 7 residuals are run on the 5 data sets and the residuals in the fault free case are shown in the plot below where the dashed lines correspond to thresholds selected to achieve a 1% false alarm probability.

The generated code from last section is run using the single Matlab call

r = ResGen_1650_74(z, state_init, params, Ts); where z is a matrix with the measurements, the struct state_init

gives the initial state, params the model parameters, and

Ts the sampling time. It takes about 0.55 seconds to evaluate a

residual for 12 minutes of 1kHz sampled data on a 2016 Macbook Pro

which corresponds to about 1500 times faster than real-time.

The residuals for data with a fault in the air-flow sensor are

Fault Isolation Performance

According to the fault signature matrix above, the

red colored residuals should be sensitive to the air-flow sensor fault

but not the blue colored residuals. The fault is present during the

gray shaded intervals, i.e., the fault is injected intermittently. The

blue colored residuals are not sensitive to the fault as expected and

residuals 1, 2, and 5 are above the dashed thresholds when the fault is

present. Residual 3 should be sensitive to this fault but the fault to

noise ratio is apparently too low for this fault, but is selected for

its ability to detect fault fyp_ic.

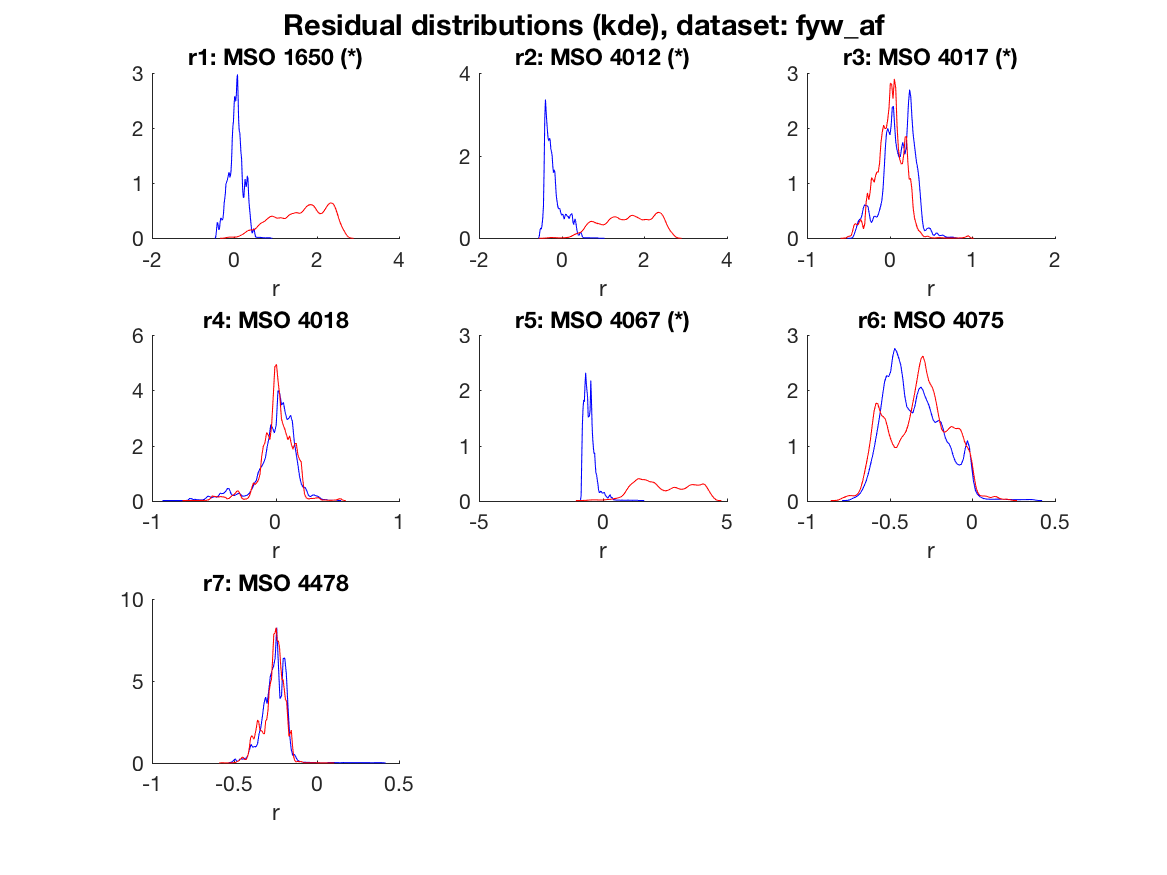

The figure below shows in blue the distributions of the residuals in the fault free case and in red the distributions of the residuals for an air-flow sensor fault. It is clear that residuals 1, 2, and 5 are good at detecting this fault since the residual distributions change significantly.

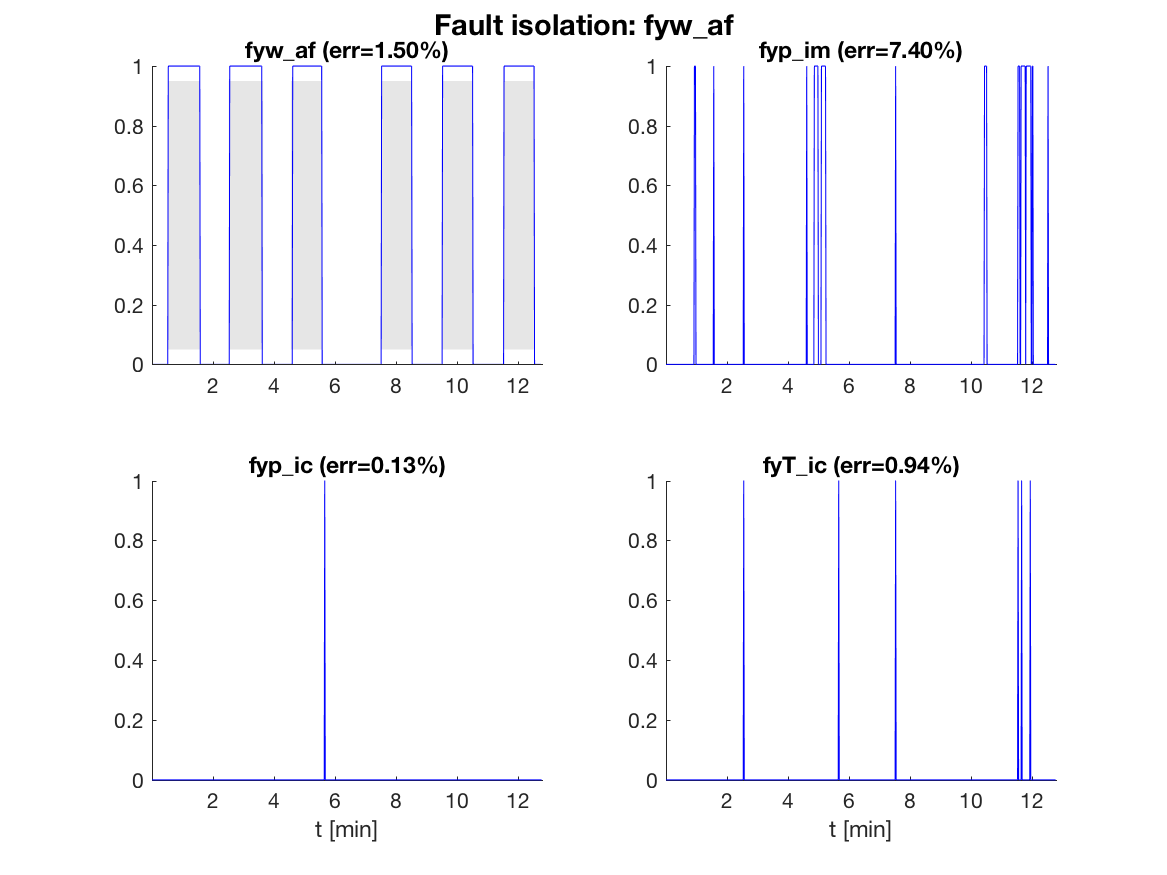

Given the residuals and thresholds, the consistency based diagnosis candidates as a function of time, in the case of an air mass-flow sensor fault, are

In the figure, a 1 means that the fault is a diagnosis and a

0 that it is not. The percentage of time where there is an isolation

error is shown above each plot. Here, no post-processing is performed,

and the error can be improved by post-filtering or applying adaptive

thresholds, maybe at the cost of a delayed detection.

It is clear that the fault isolation reliably indicates the correct

fault fyw_af and isolates reliably from fyp_ic and

fyT_ic but has a little more difficulty isolating from fault

fyp_im.

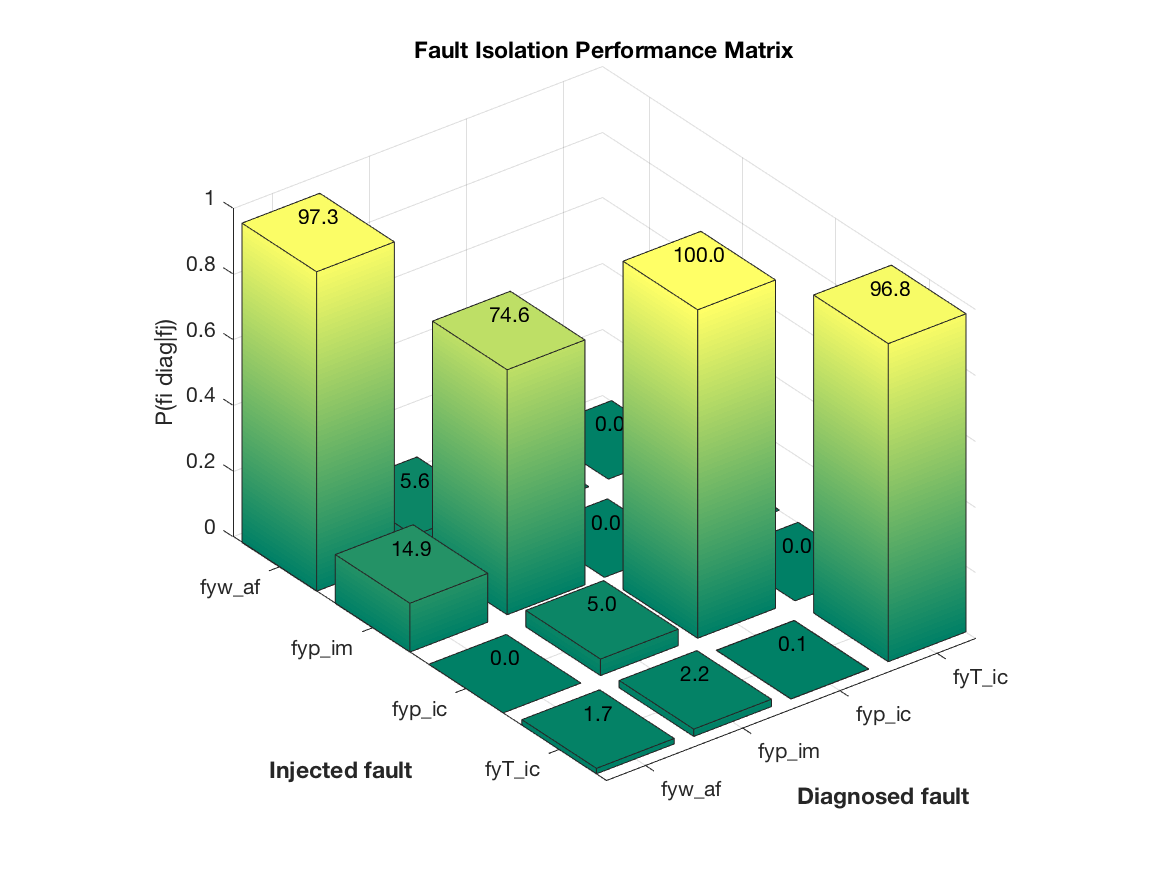

To summarize the performance of the generated diagnosis system, the confusion matrix is illustrated using a 3D-plot

Here, the probability of correct isolation is plotted, and a perfect system

would correspond to a diagonal with probability 1. It is clear from the figure

that faults fyw_af, fyp_ic, and fyT_ic can be reliably isolated. Fault fyp_im

however can be reliably detected but is sometimes difficult to isolate from fyw_af.